Post waste

Turning mine site waste into copper resources

challenge

What’s the problem we’re trying to

solve?

Across the world, mine waste piles contain hundreds of billions of tons of copper locked away in forms that are too complex, costly, or polluting to extract using today’s standard mining technologies. These dormant materials sit idle — a lost resource and an ongoing environmental risk.

At the same time, the global demand for copper is skyrocketing, driven by the expansion of electric vehicles, renewable energy, and next-generation electronics. We urgently need new ways to meet this demand without expanding the environmental footprint of mining.

solution

How does this research provide a solution?

This project is reimagining mine waste — not as a burden, but as a potential copper resource that could be unlocked through sustainable innovation.

The idea is to create ecosystems-of-resources: integrated systems of biology, materials science, and engineering that work together to extract copper from waste while simultaneously remediating environmental harm. By combining advanced technologies with natural processes, we can recover copper from materials once considered worthless — and in doing so, turn waste sites into productive, cleaner landscapes.

process

What exactly are we doing?

The Post Waste work package is focused on designing and testing a new generation of solutions that can operate directly at mine sites. This includes:

- Advanced biomining and engineered platforms: Developing systems to extract copper efficiently from a wide range of waste streams, including tailings, slags, and low-grade ores.

- Engineered biomaterials and fabricated materials: Creating smart materials that selectively recover copper and contribute to site remediation.

- Integrated biological systems: Using microbial and plant-based tools to aid in copper extraction and environmental recovery.

- Sustainability frameworks: Including water use, carbon capture, and pathways for technology adoption and knowledge transfer in every stage of development.

All of these components are designed to work together — as an ecosystem — and will be tested across multiple mine sites to assess their real-world impact, adaptability, and effectiveness.

team

Who’s involved?

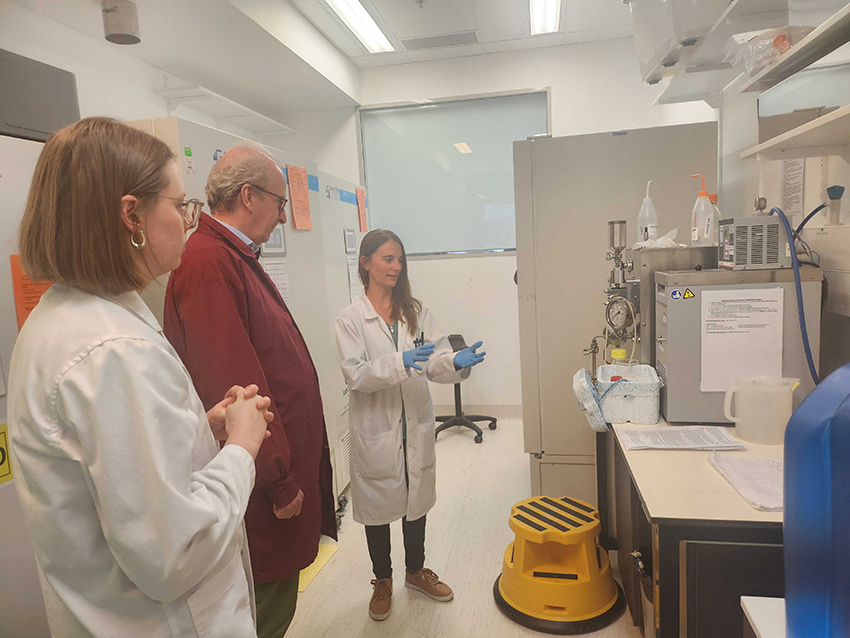

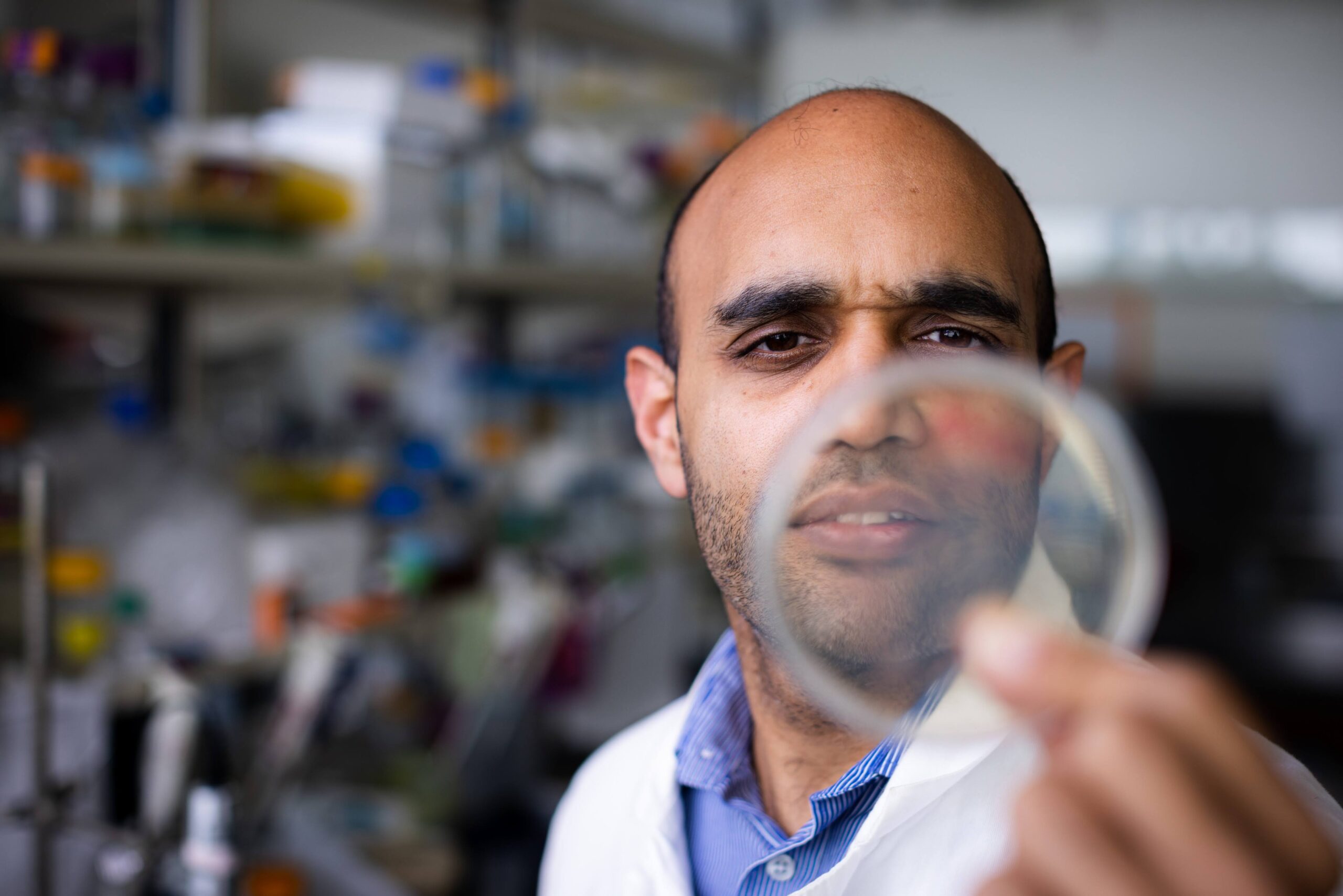

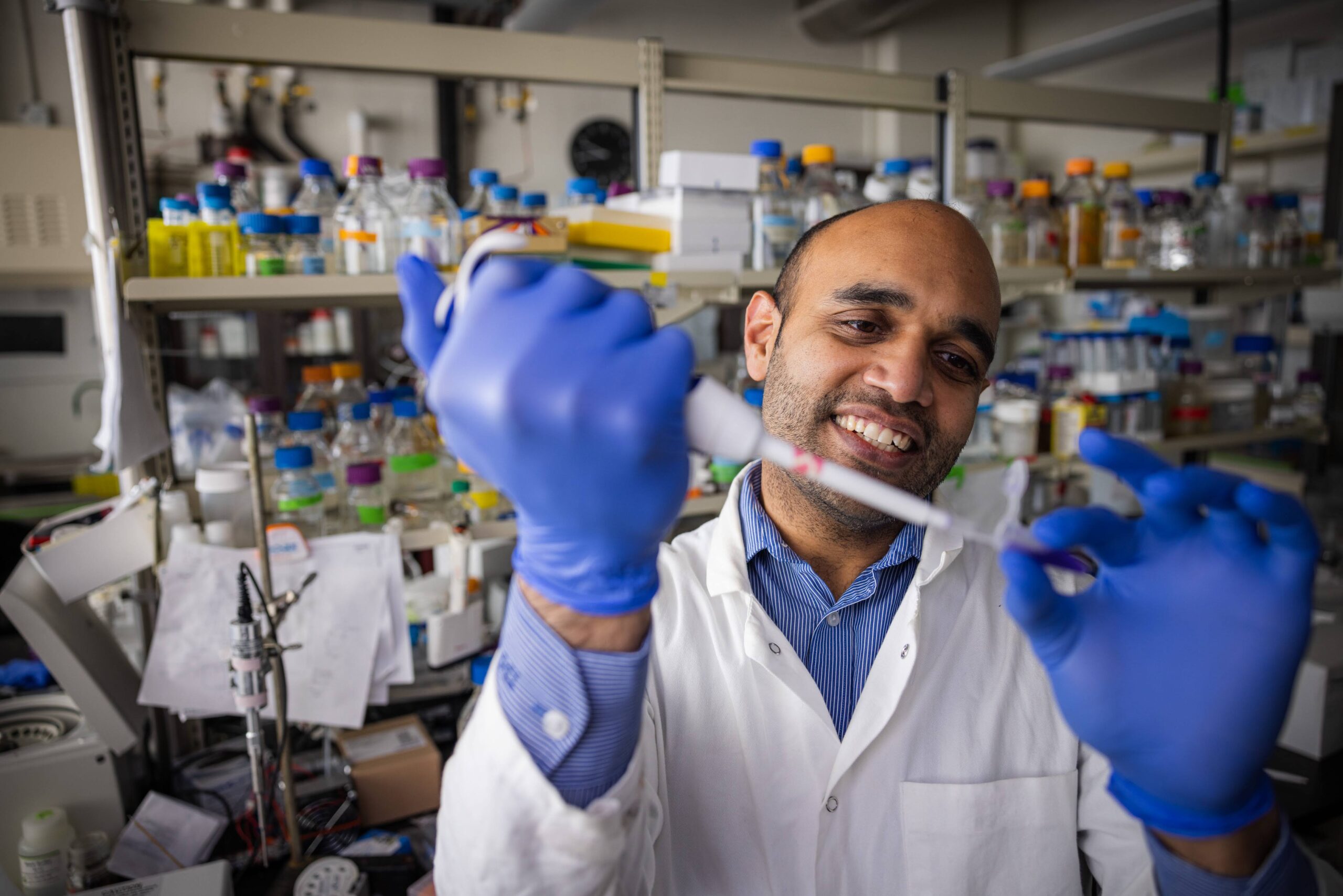

This research brings together an interdisciplinary team of leaders in plant sciences, bioengineering, materials innovation, and environmental systems:

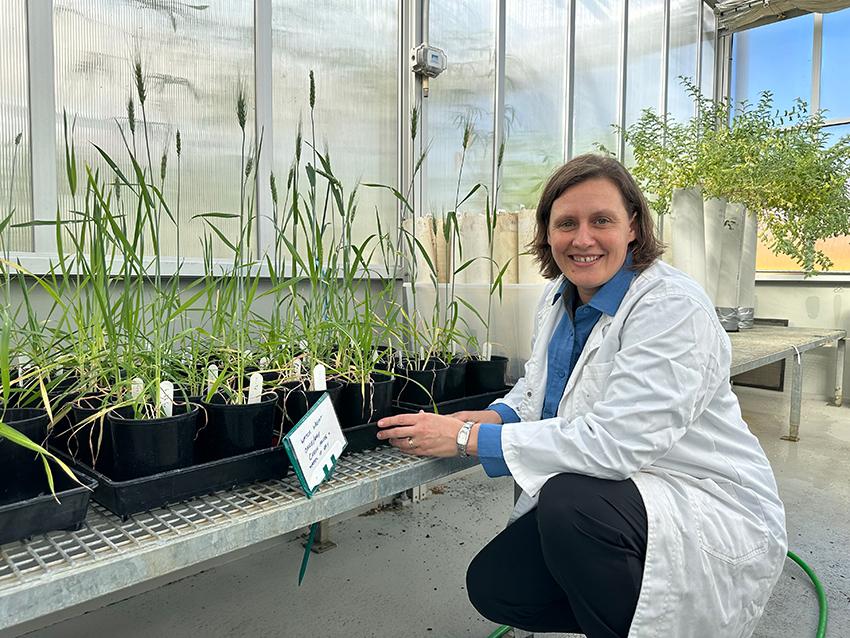

- Caitlin Byrt – Australian National University

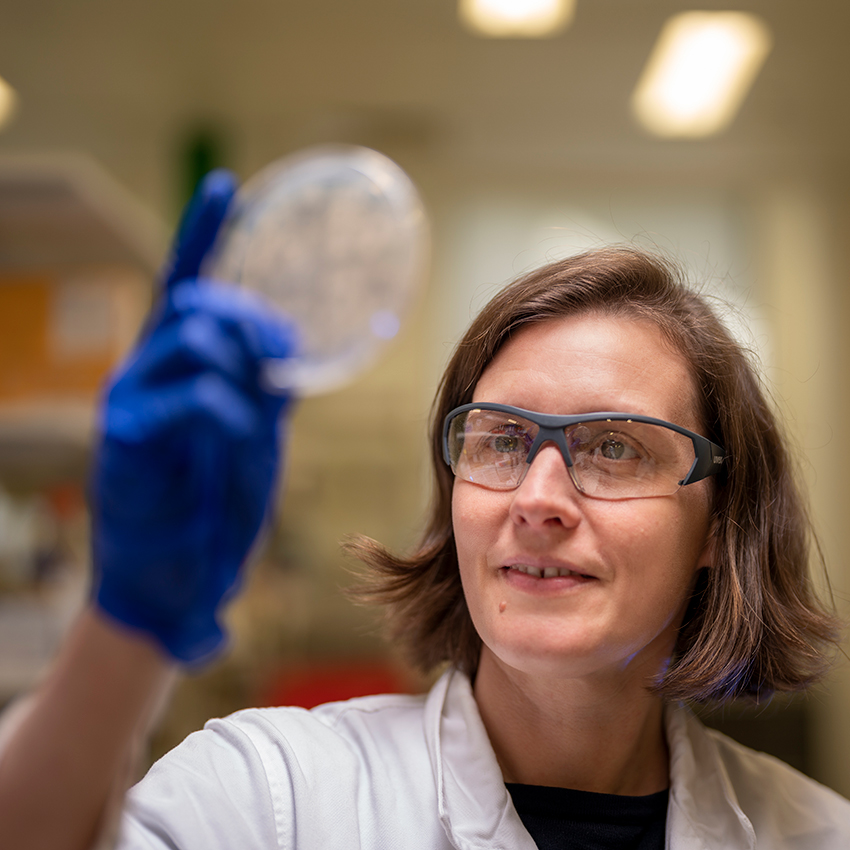

- Elena Dieckmann– Imperial College London

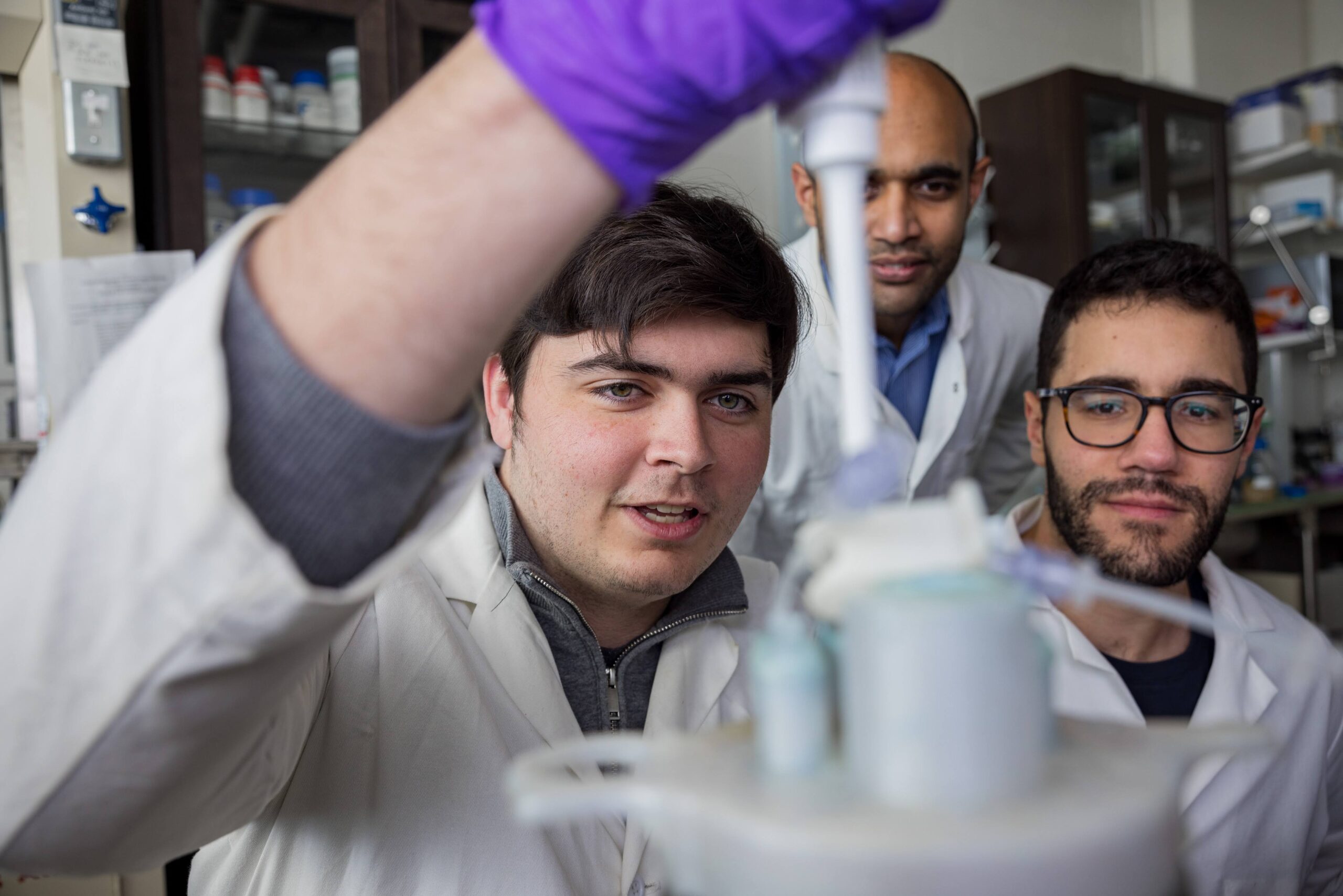

- Vikramaditya Yadav– University of British Columbia

Together, they’re pioneering a new way to think about circularity in the copper supply chain — one that adds value while cleaning up the legacy of past mining.

goals

What are our objectives and long-term goals?

- Transform mine waste into a significant, sustainable source of copper

- Reduce the environmental footprint of copper mining and processing

- Design integrated recovery and remediation systems that are site-adaptable

- Enable cost-effective, deployable solutions that can work globally

- Advance responsible innovation with benefits for industry, environment, and local communities

This project not only tackles copper recovery — it redefines what mining waste can be, offering a scalable model for resource circularity in the clean energy transition.

Sign up

to our newsletter

Stay informed with the latest research breakthroughs, expert insights and updates from the Rio Tinto Centre for Future Materials. Sign up to our newsletter to connect with a global community driving innovation in sustainable materials and the energy transition.